Health risk assessment of emissions from a Gypsum plant using AERMOD

Marzieh Makaremi1, Nabiollah mansouri2*, Alirezavafaeinajad3, Mohammad hasanBehzadi4, Seyed Alirezamirzahossieni5

Affiliation

1Department of Environmental Engineering, Faculty of Natural Resources and Environmental, Tehran Science and Research Branch, Islamic Azad University, Tehran, Iran

2Faculty of Natural Resources and Environmental, Tehran Science and Research Branch, Islamic Azad University, Tehran, Iran

3Faculty of Civil, Water and Environmental Engineering, Shahid Beheshti University, Tehran, Iran

4Faculty of Foundational science, Tehran Science and Research Branch, Islamic Azad University, Tehran, Iran

5Faculty of Natural Resources and Environmental, Tehran Science and Research Branch, Islamic Azad University, Tehran, Iran

Corresponding Author

Nabiollah mansouri, Full Professor, Faculty of Natural Resources and Environmental, Tehran Science and Research Branch, Islamic Azad University, Tehran, Iran, Tel/ Fax: 02122060435; E-mail: nmansourin@gmail.com

Citation

Makaremi, M., et al. Health risk assessment of emissions from a Gypsum plant using AERMOD. (2019) J Environ Health Sci 5(2): 63-70.

Copy rights

© 2019 Makaremi, M. This is an Open access article distributed under the terms of Creative Commons Attribution 4.0 International License.

Keywords

AERMOD; Risk assessment; Gypsum plant; Heavy metal

Abstract

Carcinogenic and non carcinogenic risk assessment for a Gypsum plant was studied in this paper. The dispersion of PM10 was predicted around the plant by AEMROD model. The AERMOD predictions were verified with measurement and the application of AEMROD for the assessment of health risk was studied. Carcinogenic and non-carcinogenic risk assessment due to heavy metals in air was assessed both for plant worker and resident of neighboring cities. Carcinogenic risk assessment was compared with the hospital data. The results of the assessment show ability of AERMOD as a risk assessment tool. The results indicate that the worker and residents are not exposed to hazardous level of risk HQ < 1. The risk of plant- activity- induced cancer was about 976 per 1 million workers. This risk for permanent resident people in neighborhood cities was about 220 per 1 million. The risk of cancer due to all sources activities was about 598 per 1 million people. The contribution of Gypsum plant in cancer disease is about 36%. The findings indicate that there is a need to have a detailed assessment on the short- and long-term health effects of the emission from Gypsum plant in ZARCH.

Introduction

Gaussian dispersion models were widely used for sampling network design, concentration prediction, environmental management scenarios and EIA (EPA, 2005). Another application of these models is in risk assessment. Acceptable accuracy, quick setup, relative simplicity of use, robust predictions, applicability for wide range of cases in different atmospheric condition, are the major advantages of these models (EPA. Human Health Risk Assessment, 2005). Several studies indicated that Gaussian models are suitable in predicting air pollution dispersion (Akula, V., et al, 2018; Amini, M., et al, 2018).

Dispersion modeling and Health risk assessment are conducted in tandem (Karademir, A, 2004). ADMS (Advanced Dispersion Modeling System) and ISCST3 (Industrial source complex short term version 3) are two examples of these models(López, M.T., et al, 2005). AERMOD (AMS/EPA Regulatory Model) is an air dispersion model based on PBL theory. AERMOD could incorporate advanced depositional parameters, local terrain effects, PRIME building downwash algorithms and advanced meteorological turbulence calculations. AERMOD was used for risk assessment of a number of pollutants such as SO2, NO2, mercury and PM10 and these studies indicated that Gaussian dispersion models are suitable in forecasting pollutant dispersion and risk assessment (Hagan, N., et al, 2011; Ding, F., 2012; Mokhtar, M.M., et al., 2014; Afzali, A., et al., 2017). International Agency for Research on Cancer (IARC) has considered the carcinogenic and neurotoxicity effects of heavy metals (IARC, 1990; 1993).

Based on the World Health Organization studies, more than 2.4 million people die each year as a result of air pollutants. Moreover, epidemiological studies show that more than 600,000 people die each year from cardiopulmonary problems due to breathing fine particles in the polluted air (DOE, 2009). Industrial complex is one of the biggest contributors to air pollution, especially when located near the urban areas. The Gypsum plant is one of the important air pollution sources which contribute significantly to decrease air quality. The key pollutant in these industries is PM10 developed during miscellaneous processes. The principal aim of pollution control in the Gypsum industry is to minimize emission by reducing the mass load emitted from the point, area and line sources (Hagan, N., et al, 2011). Calcium sulfate dehydrate (CaSO4 2H2O) or Gypsum is a white or gray naturally occurring mineral. Raw Gypsum ore is processed into a variety of products such as a soil conditioner, industrial and building plasters, Portland cement additive and Gypsum wallboard (EPAAP, 1995). Gypsum ore, from underground mines and quarries, is crushed and stockpiled near a plant. The dominant pollutant in Gypsum processing plants is PM10 (EPAAP, 1995).

Area of study

The case study is ZARCH Gypsum plant in 240148.79 m E and 3543795.85 m N zone 40S. There are several sources of PM10 in this industry, including, point, line and area sources. The point sources like stacks, line sources like conveyor and roads, area sources like piles and wind erosion from surrounding areas. ZARCH plant brings Gypsum the total output to 250 metric tons per day. The schematic view of site plan is shown in Fig. 1.

Figure 1: Aerial view of ZARCH Gypsum plant

The emission rates of sources were estimated as follows:

• Direct measurement of emission

• Indirect measurement (using measurement results in other same companies if exist)

• The use of modeling tools like CFD

• The use of EPA emission rates (ap42)

There are about 10 miscellaneous sources of PM10 in this Company. The sources and emission of them are mentioned in table 1.

Table 1: PM10 emission rate for ZARCH Gypsum plant

|

process and unit |

Method of emission calculation |

contribution |

g/s1 |

|

stack |

measurement |

7% |

0.0144 |

|

drying |

measurement and emission factor |

10% |

0.02 |

|

grinding |

measurement and emission factor |

34% |

0.07 |

|

conveyors |

emission factor |

0% |

2.6E-4 |

|

wind erosion and miscellaneous |

emission factor and CFD-Fluent2 |

49% |

0.1 |

|

Total |

0.20466 |

||

1The emissions from all sources have been converted to g/s.

2The modified Fluent software has been used.

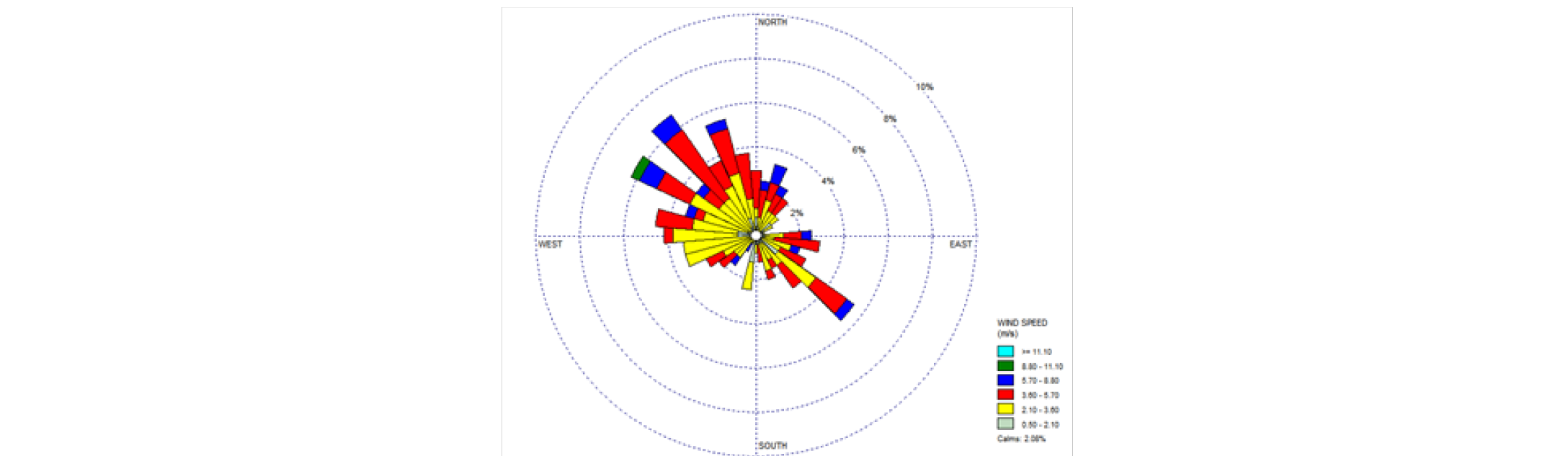

The area of modeling is the radius of 7.5 km around the company and the topographical conditions were flat and elevated. The area of modeling is urban accordance to (Gimson, N., et al, 2007). The AERMOD was implemented during 2017-2018. The maximum wind velocity in 10 m was 10 m/s and the wind rose of the area is shown in Fig 2.

Figure 2: Wind rose of 2017-2018 for ZARCH Gypsum plant

The DEM file with 20 m vertical and 30 m horizontal resolution has been used for AERMAP module.

Materials and Methods

The AERMOD was implemented in radius of 7.5 km around Company. The annual and maximum 1hr concentration of PM10 was predicted. These concentrations were used for risk assessment both for short- and long- term for workers and resident in neighboring cities. Carcinogenic and non-carcinogenic effect was calculated for heavy metals in Gypsum composition. The Gypsum sample was analyzed with XRF method and the fraction of each tracer elements within sample is determined. Table 2 shows the results of XRF analysis.

Table 2: XRF analysis of Gypsum sampling inside Company

|

LOI |

SO3 |

P2O5 |

MnO |

TiO2 |

|

||

|

5.58 |

29.89 |

0.026 |

9.03 |

0.004 |

|

||

|

MgO |

K2O |

Na2O |

CaO |

Fe2O3 |

AL2O3 |

SiO2 |

|

|

2.11 |

0.05 |

10.05 |

25.30 |

5.11 |

8.17 |

2.86 |

|

|

Cr |

Ni |

Pb |

Zn |

Cu |

Sr |

Ba |

Cl |

|

0.0241 |

0.0183 |

0.023 |

0.0016 |

0.0012 |

0.7286 |

0.001 |

0.0068 |

|

|

|

|

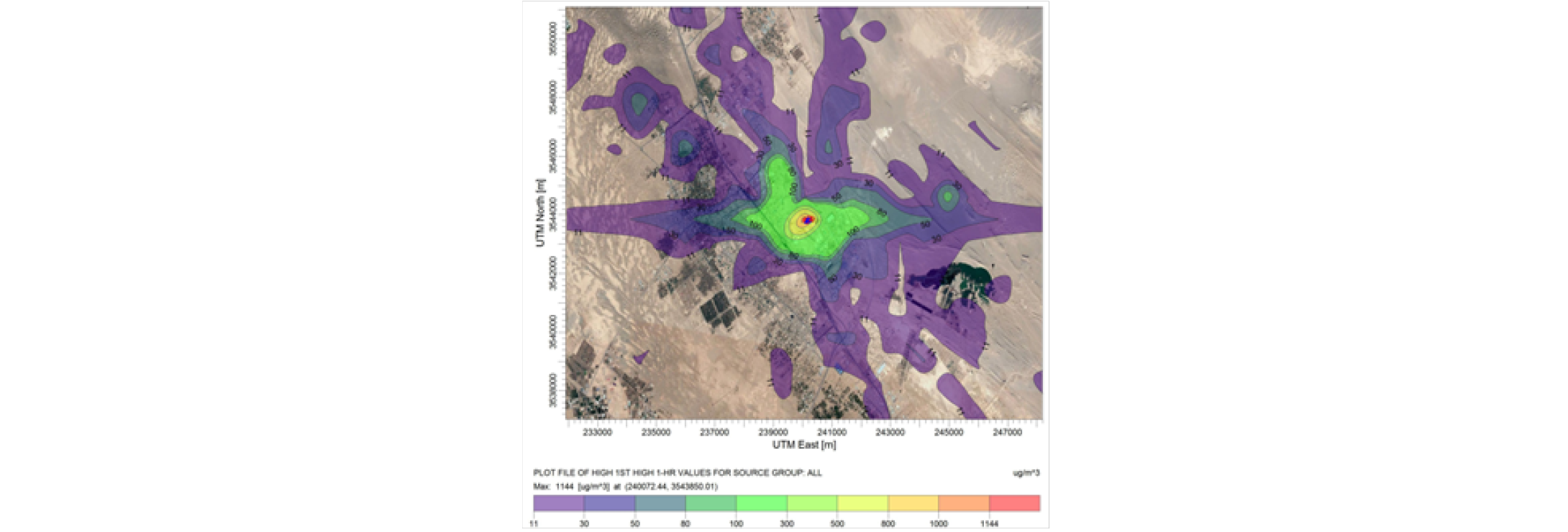

Figure 3: Maximum 1 hr PM10 concentration dispersion around Company (µg/m3)

Figure 4: Annual PM10 concentration ¬dispersion around Company (µg/m3)

The carcinogenic risk assessment for all sources also was calculated and the contribution of Gypsum plant in carcinogenic risk assessment was determined.

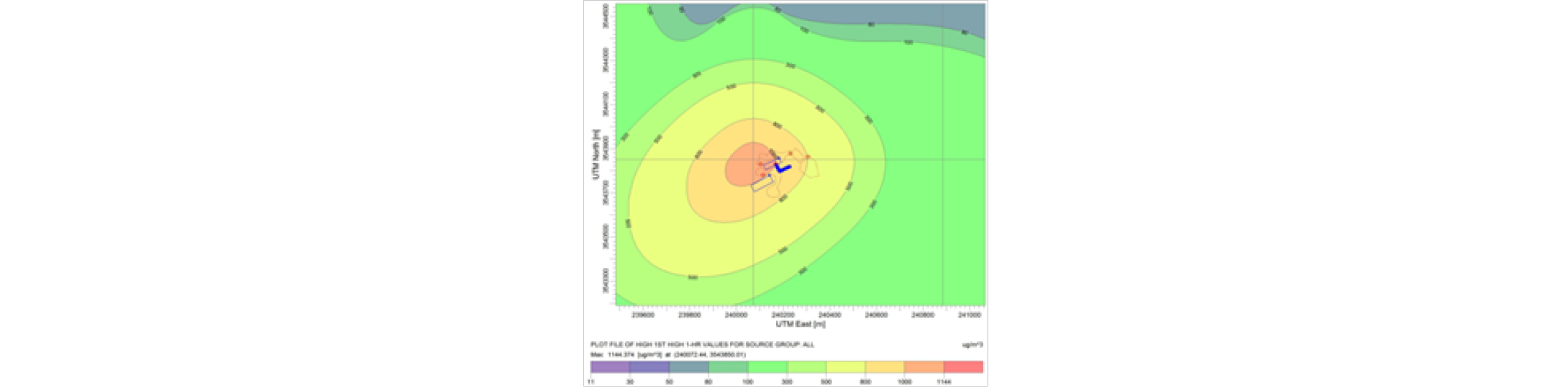

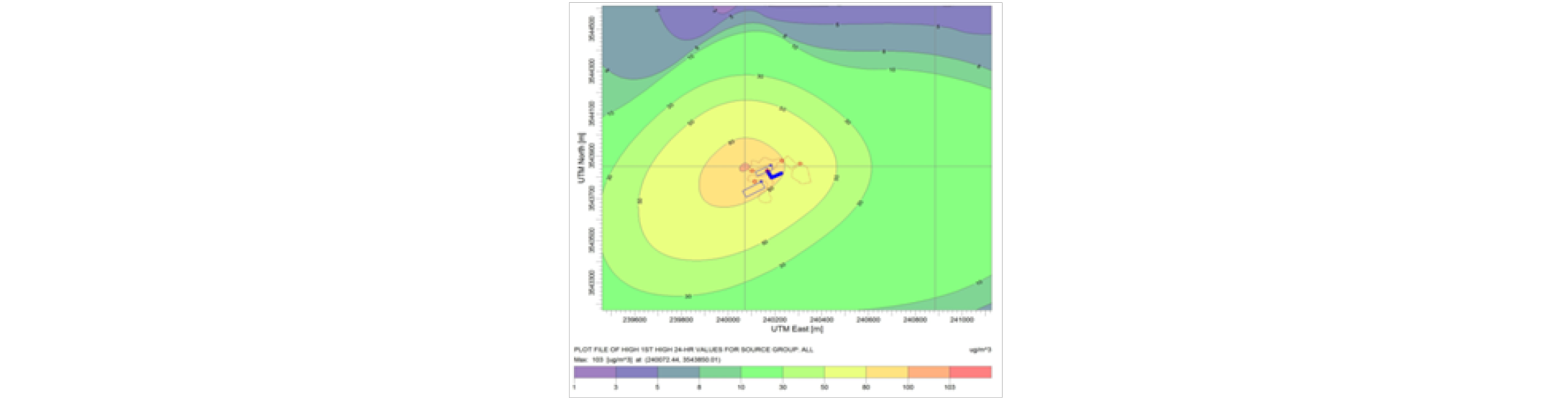

Figures above suggest that annual concentration of PM10 around the company does not exceed the annual standard of 20 µg/m3. 2D contours of the annual PM10 concentration and maximum 1hr concentration of PM10 inside the company are shown in Fig5. and Fig 6. The workers are exposed to these levels of concentration 8 hr a day.

Figure 5: Maximum 1 hr PM10 concentration dispersion inside Company (µg/m3)

Figure 6: Annual PM10 concentration dispersion inside Company (µg/m3)

Table 3: XRF analysis of sampling in center of ZARCH city

|

LOI |

SO3 |

P2O5 |

MnO |

TiO2 |

|

||

|

20.88 |

44.09 |

0.026 |

0.001 |

0.014 |

|

||

|

MgO |

K2O |

Na2O |

CaO |

Fe2O3 |

Al2O3 |

SiO2 |

|

|

0.67 |

0.05 |

0.03 |

31.77 |

0.11 |

0.17 |

0.86 |

|

|

Cr |

Ni |

Pb |

Zn |

Cu |

Sr |

Ba |

Cl |

|

0.0191 |

0.0033 |

0.0006 |

0.0007 |

0.0002 |

1.0286 |

0.001 |

0.0068 |

Figures above suggest that the annual concentration of PM10 around Company exceed the annual standard of 20 µg/m3 and workers inhale high concentration of PM10 and also heavy metals. Several studies referred to the methodology of health risk assessment (HRA) (Louvar, J.F., et al, 1998; EPA, 2005; DOE, 2009; MOH, 2011). For short- and long-term health risk assessment both for carcinogenic and non-carcinogenic effects, the exposure should be compared to the reference levels. Toxicological parameters such as Reference Concentration (1RfC) and Reference Dose (RfD) are used to describe the relationship. The RfC is an estimated daily concentration of toxicant in air that can be tolerated by human without adverse effects, while the RfD is an estimated daily oral exposure of a toxicant (Louvar, J.F., et al, 1998). In table 4 and table 5, IRIS reference guide are given.

Table 4: Acute and Chronic reference concentration for non-carcinogenic assessment (IRIS 2013)

|

Pollutants (mg/m3) |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Acute RfC |

- |

- |

6E-3 |

- |

5E-4 |

9E-3 |

- |

2E-4 |

- |

|

Chronic RfC |

- |

1E-4 |

9E-5 |

- |

2.5E-5 |

3E-4 |

- |

1.5E-5 |

1.5E-4 |

Table 5: Inhalation unit risk factor for carcinogenic effect (IRIS 2013)

|

Pollutants (µg/m3) |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

URF |

- |

1.2E-2 |

2.4E-4 |

- |

5E-4 |

1E-3 |

- |

4.3E-3 |

- |

Non-carcinogenic risk assessment due to Gypsum plant activity

Risk characterization for non-carcinogenic health risk due to inhalation is performed by quantifying the hazard using Hazard Quotient (EPA, 2005; DEO, 2009). For HQ < 1, the potential risk is within acceptable level and no action required reducing the pollutant’s level. In the other words HQ < 1 is considered safe. It should be noted that HQ > 1 does not necessarily means a likelihood of adverse effects. HQ > 1 is more suitable to be used as an indication that a potential risk exists for adverse health effects (EPA, 2013).

Non-carcinogenic risk assessment of heavy metals due to Gypsum plant activity for permanent resident in neighborhood cities was calculated and given in table 6. The annual PM10 concentration from AERMOD was used and the fraction of heavy metals and CDI calculated for 24 hr a day.

Table 6: Non-carcinogenic risk assessment due to Gypsum plant activity for permanent resident

|

Heavy metal |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Short-term risk |

- |

- |

1.10E-05 |

- |

0.00E+00 |

4.06E-05 |

- |

0.00E+00 |

- |

|

Long-term risk |

- |

3.85E-05 |

7.37E-06 |

- |

0.00E+00 |

8.11E-06 |

- |

0.00E+00 |

8.04E-07 |

Table 6 suggests that, the risk of non-carcinogenic effect (HQ) is less than 1, indicating that heavy metals dispersion is unlikely to cause health risk to population within 7.5 km radius from the Gypsum plant. For workers, the risk assessment was calculated in 2 steps. The first is 8 hr activity in Gypsum plant and, second one is 16 hr activity in the cities after work. Non-carcinogenic risk assessment of heavy metals due to Gypsum plant activity for workers was calculated and is given in tables 7 and 8.

Table 7: Non-carcinogenic risk assessmentdue to Gypsum plant activity for workersin the Company

|

Heavy metal |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Short-term risk |

- |

- |

4.21E-06 |

- |

0.00E+00 |

1.54E-05 |

- |

0.00E+00 |

- |

|

Long-term risk |

- |

1.46E-04 |

2.81E-05 |

- |

0.00E+00 |

3.09E-05 |

- |

0.00E+00 |

3.06E-06 |

Table 8: Non-carcinogenic risk assessment due to Gypsum plant activity for workers in the cities

|

Heavy metal |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Short-term risk |

- |

- |

7.37E-06 |

- |

0.00E+00 |

2.70E-05 |

- |

0.00E+00 |

- |

|

Long-term risk |

- |

2.56E-05 |

4.91E-06 |

- |

0.00E+00 |

5.41E-06 |

- |

0.00E+00 |

5.36E-07 |

The total risk assessment for workers is given in table 9.

Table 9: Total non-carcinogenic risk assessment due to Gypsum plant activity for workers

|

Heavy metal |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Totalshort-term risk |

- |

- |

1.16E-05 |

- |

0 |

4.25E-05 |

- |

0 |

- |

|

Total long-term risk |

- |

0.000172 |

3.3E-05 |

- |

0 |

3.63E-05 |

- |

0 |

3.6E-06 |

Table 9 suggests that, the risk of non-carcinogenic health is less than 1 and therefore heavy metals dispersion is unlikely to cause adverse health effects on workers.

Carcinogenic risk assessment due to Gypsum plant activity

For inhalation- induced carcinogenic risk, the life-time cancer risk (LCR) is estimated (EPA, 2005; DEO, 2009). Threshold of cancer risk “accept-ability” varies among countries, states, and different cities of the same state (Kelly, K.E, 1991). The common standard risk which is adopted as “acceptable risk” is about 10E−6 (one person in a million). This risk value is also known as the minimum risk, which is considered negligible. Clay (1991) also mentioned that the risk level of 10E-6 to10E-4 is judged as a range of “generally acceptable risks” where10E-4 may be exceeded when there is a need to balance the costs and benefits of remedial actions. It should be noted that acceptability of cancer risk could vary based on several factors, such as existing chemical standard (Clay, D.R, 1991), population risk (Travis, C.C, 1987), degree of control over exposures (Kelly, K.E, 1991), etc. Nevertheless, in this paper, the risk level of 10E−6to 10E−4 was used as the acceptable risk.

Carcinogenic risk assessment of heavy metals due to Gypsum plant activity for permanent resident in neighborhood cities was calculated and given in table 10. The annual PM10 concentration from AERMOD was used and CDI calculated for 24 hr a day.

Table 10 suggests that, the probability to develop cancer due to short- and long-term dispersion of heavy metals from Gypsum plant is higher than the threshold of 1E-6 to 1E-4. The total risk of cancer causes is about 220 people per 1 million for people residing in the neighborhood cities. For workers, the carcinogenic risk assessment was calculated in 2 steps like the former one. The first one is 8 hr activity in Company and the second one is 16 hr after work in the cities. Carcinogenic risk assessment of heavy metals due to Gypsum plant activity for workers was calculated and given in tables 11 and 12. The annual PM10 concentration from AERMOD was used and CDI calculated for 8 hr and 16 hr a day.

Table 10: Carcinogenic risk assessment due to Gypsum plant activity for permanent resident

|

Heavy metal |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Long term carcinogenic Risk |

- |

1.98E-05 |

6.83E-08 |

0.00E+00 |

0.00E+00 |

- |

- |

0.00E+00 |

- |

|

Short term carcinogenic Risk |

- |

1.98E-04 |

6.83E-07 |

0.00E+00 |

0.00E+00 |

- |

- |

0.00E+00 |

- |

|

Total long term |

1.98E-05 |

||||||||

|

Total short term |

1.98E-04 |

||||||||

Table 11: Carcinogenic risk assessment due to Gypsum plant activity for workers in the Company

|

Heavy metal |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Long term carcinogenic Risk |

- |

7.53E-05 |

2.60E-07 |

0.00E+00 |

0.00E+00 |

- |

- |

0.00E+00 |

- |

|

Short term carcinogenic Risk |

- |

7.53E-04 |

2.60E-06 |

0.00E+00 |

0.00E+00 |

- |

- |

0.00E+00 |

- |

|

Total long term |

7.55E-05 |

||||||||

|

Total short term |

7.55E-04 |

||||||||

Table 12: Carcinogenic risk assessment due to Gypsum plant activity for workers in the cities

|

Heavy metal |

Cu |

Cr |

Ni |

Sr |

Ba |

Hg |

Zn |

As |

Pb |

|

Long term carcinogenic Risk |

- |

1.32E-05 |

4.55E-08 |

0.00E+00 |

0.00E+00 |

- |

- |

0.00E+00 |

- |

|

Short term carcinogenic Risk |

- |

1.32E-04 |

4.55E-07 |

0.00E+00 |

0.00E+00 |

- |

- |

0.00E+00 |

- |

|

Total long term |

1.32E-05 |

||||||||

|

Total short term |

1.32E-04 |

||||||||

The total carcinogenic risk assessment for workers has been depicted in table 13

Table 13 suggests that, the total short- and long-term risk of cancer causes for workers is about 976 people per 1 million workers. Table 13 suggests that, the probability to develop cancer due to short- and long-term dispersion of heavy metals from Gypsum plant is higher than the threshold of 1E-6 to 1E-4.

Table 13: Total carcinogenic risk assessment due to Gypsum plant activity for workers

|

Total long term |

8.88E-05 |

|

Total short term |

8.88E-04 |

Carcinogenic risk assessment due to all sources

In this section, the carcinogenic risk assessment due to all- sources pollution was calculated for permanent resident of the neighboring cities. The AERMOD annual and 1 hr maximum prediction was used and heavy metal fraction in PM10 sample from the center of the ZARCH city was used for risk assessment. This PM10 sample has three more heavy metals than Gypsum sample includes Mn, Fe and Cd. The results were given in table 14.

Table 14: Carcinogenic risk assessment due to all sources activity for permanent resident

|

Heavy metal |

Cr |

Ni |

Sr |

Hg |

Mn |

Fe |

Cd |

As |

|

Long term carcinogenic Risk |

6.21E-05 |

1.03E-06 |

0.00E+00 |

8.63E-07 |

0.00E+00 |

0.00E+00 |

2.33E-06 |

3.34E-05 |

|

Short term carcinogenic Risk |

3.10E-04 |

5.17E-06 |

0.00E+00 |

4.32E-06 |

0.00E+00 |

0.00E+00 |

1.17E-05 |

1.67E-04 |

|

Total long term |

9.97E-05 |

|||||||

|

Total short term |

4.99E-04 |

|||||||

Table 14 suggests that, total short- and long-term carcinogenic risk assessment due to all sources is about 598 people per 1 million permanent residents. The contribution of as is about 190 persons, Cr = 370, Cd =13, Ni = 6 and Hg = 5 people. The probability to develop cancer due to short- and long-term dispersion of heavy metals from all sources is higher than the threshold of 1E-6 to 1E-4. As shown in table 10, the carcinogenic risk assessment due to Gypsum activities was about 220 per 1 million people. In other words, the contribution of Gypsum plant in total carcinogenic risk assessment in the city is about 36%. In table 15, the population information of the neighboring cities was depicted and the number of cancer causes for each city was calculated.

Table 15: The number of city’s resident getting cancer

|

City |

Population |

Short-term |

Long-term |

Total |

||

|

Number of person which may getting cancer during life |

Number of person which may getting cancer during life |

|||||

|

Due to Gypsum Company |

Due to Gypsum Company |

Due to all sources |

Due to all sources |

|||

|

ZARCH |

20,857 |

4 |

0.4 |

2 |

10 |

16.4 |

|

ASHKEZAR |

15,663 |

3 |

0.3 |

1.5 |

7.5 |

12.3 |

|

FIROOZABAD |

10,000 |

2 |

0.2 |

1 |

5 |

8.2 |

|

REZVANSHAHR |

10,000 |

2 |

0.2 |

1 |

5 |

8.2 |

|

SHAHEDIEH |

16,500 |

3.3 |

0.33 |

1.6 |

8.25 |

13.48 |

Conclusion

In this study, heavy metals emission from ZARCH Gypsum plant was predicted with AERMOD. The annual and maximum 1 hr concentration of heavy metals was used for carcinogenic and non-carcinogenic risk assessment for short- and long-term dispersion of the studied pollutants. HRA was calculated both for worker and people residing in the neighboring cities.

For non-carcinogenic health risk, short- and long-term dispersion indicated an acceptable level of pollutant concentration. For heavy metals, the short- and long-term dispersion is unlikely to cause health risk to population residing within 7.5 km radius of the studied plant.

For carcinogenic health risk, there is a probability to develop cancer due to long and short-term dispersion of heavy metals specially Cr and As. The findings indicate that a detailed assessment of the short- and long-term health effects of the emissions from Gypsum plant in ZARCH is necessary.

References

- Afzali, A., Rashid, M., Afzali, M., et al. Prediction of air pollutants concentration from multiple sources using AERMOD coupled with WRF prognostic model. (2017) J Cleaner Production 166: 1216-1225.

- Akula, V., Nico, S. Modeling dispersion at city scale. (2018) J Urban Transportation and Air Pollution 139-146.

- Amini, M., Enayati, F., Heist, S., et al. Modeling dispersion for of emissions from depressed roadway. (2018) J Atmos Environ186: 189-197.

- Ashrafi, Kh., Kalhor, M., Esfahaniyan, V. Numerical simulation of aerodynamic suspension of particles during wind erosion. (2015) J Environ Earth Sci 74(2): 1569-1578.

- Clay, D.R. Role of the Baseline Risk Assessment in Superfund Remedy Selection Decisions (Memorandum from D. R. Clay, OSWER 9355.0-30, April 1991). Washington, DC, United States.1991

PubMed│Crossref│Others

- DOE. Guidance Document on Health Impact Assessment (HIA) in Environmental Impact Assessment (EIA). Department of Environment (DOE). Malaysia.2009.

PubMed│Crossref│Others

- Ding, F. Analysis of upper air environmental impact of pollutants discharged by power plant. (2012) J Pro Environ Sci 13: 1149–1154.

- EPA. Revision to the Guideline on Air Quality Models: Adoption of a Preferred General Purpose (Flat and Complex Terrain) Dispersion Model and Other Revisions. 40 CFR Part 51, (AH–FRL–7990–9) RIN 2060–AK60, Federal Register/ 2005, Vol. 70, No. 216 / Rules and Regulations.2005.

PubMed│Crossref│Others

- EPA. Human Health Risk Assessment Protocol for Hazardous Waste Combustion Facilities.2005.

PubMed│Crossref│Others

- EPAAP 42 Compilation of Air Pollutant Emission Factors. chapter 11 section 16.1995.

PubMed│Crossref│Others

- EPA .Estimated Risk: Background on Risk Characterization.2013.

PubMed│Crossref│Others

- Gimson, N., Olivares, G., Khan, B., et al. Dispersion Modeling in New Zealand, Part1–Assessment of Meteorological Models, FRST program Protecting New Zealand’s Clean Air.2007.

PubMed│Crossref│Others

- Hagan, N., Robins, N., Hsu-Kim, H., et al. Estimating historical atmospheric mercury concentrations from silver mining and their legacies in present-day surface soil in Potosí, Bolivia. (2011) J Atmos Environ 45(40): 7619–7626.

- IARC. Chromium and chromium compounds. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans. Vol. 49, Chromium, Nickel and Welding. Lyon: International Agency for Research on Cancer.1990.

PubMed│Crossref│Others

- IARC. Cadmium and cadmium compounds. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans.Vol58. Beryllium, Cadmium, Mercury and Exposures in the Glass Manufacturing Industry. Lyon: International Agency for Research on Cancer.1993.

PubMed│Crossref│Others

- Karademir, A. Health risk assessment of PCDD/F emissions from a hazardous and medical waste incinerator in Turkey. (2004) J Environ 30(8): 1027–1038.

- Kelly, K.E. The myth of 10-6 as a definition of acceptable risk Updated from a Paper Originally. In: Presented at the 84th Annual Meeting Air & Waste Management Association, Vancouver, BC. Canada, 1991.

PubMed│Crossref│Others

- López, M.T., Zuk, M., Garibay, V., et al. Health impacts from power plant emissions in Mexico. (2005) J Atmos Environ 39(7): 1199–1209.

- Louvar, J.F., Louvar, B.D. Health and Environmental Risk Analysis: Fundamentals with Applications. Prentice Hall, United States.1998.

PubMed│Crossref│Others

- Mokhtar, M.M., Hassim, M.H., Taib, R.M. Health risk assessment of emissions from a coal-fired power plant using AERMOD modelling. (2014) J Pro Safe Environ Pro 92(5): 476–485.

- MOH, Guidance Document on Health Risk Assessment for Solid Waste Management. Ministry of Health (MOH) Malaysia. 2011.

PubMed│Crossref│Others

- Torano, J.A., Rodriguez, R., Diego, I., et al. Influence of the pile shape on wind erosion CFD emission simulation. (2006) J Appl Math Model 31(11): 2487–2502.

- Travis, C.C., Crouch, E.A.C., Milson, R., et al. Cancer risk management: a review of 132 regulatory decisions. (1987) J Environ Sci Technol 21 (5): 415–420.