Keratinase a Feather Degrading Enzyme Useful for Mosquito Control

Poopathi, S1*, Murugan, K2, Selvakumari, J1, Mani, C1, Bala, P1, De Britto, R.L.J1, Pattnaik, S3, Santhosh Goud3, Prabakaran, K4

Affiliation

Vector Control Research Centre (Indian Council of Medical Research), Indira Nagar, Puducherry, India

Corresponding Author

Poopathi, S, Vector Control Research Centre (Indian Council of Medical Research), Indira Nagar, Puducherry–605006, India; E-mail: Subbiahpoopathi@rediffmail.com

Citation

Poopathi S., et al. Keratinase a Feather Degrading Enzyme Useful for Mosquito Control. (2016) Cell Immunol Serum Biol 2(2): 50-52.

Copy rights

© 2016 Poopathi S. This is an Open access article distributed under the terms of Creative Commons Attribution 4.0 International License.

Keywords

Keratinase; Bacterial forms; Enzymes

Introduction

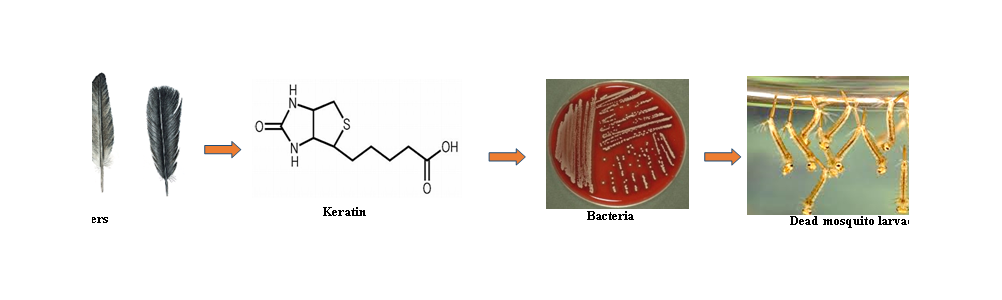

‘Keratin’ is the major structural protein present in animal feathers, hair, wool, horn and skin. Feather includes above 90% of crude protein in the form of keratin[1]. The mechanical strength of the keratin by the tight packaging of proteins in α-helix or β-sheet (α-keratin or β-keratin respectively) structures and their high level of cross-linkages by hydrogen and disulfide bonds[2]. Feather waste represents a potential protein alternative to more expensive dietary ingredients for animal feed[3]. But some keratinase producing microorganisms are converted native keratin to smaller molecular entities and consequently that can utilizes nutrient sources for the growth of bacteria[4]. In recent years, there have been several reports on the purification of Keratinase from diverse microorganisms[5]. Therefore, there is urgent requirement to find out novel enzyme which is having the ability to degrade keratin containing substrate from various sources such as poultry form and leather industries and develop enzyme purification methods. It is vital role to improve the non-polluting practice[6]. Keratinase properties based on the producers. It is generally a serine protease[7]. Occasionally, keratinase has been found to be a serine protease with a cysteine protease and a metallo protease[8]. Its optimum temperatures and pH values were reported to be 40 – 80°C and 6 – 10, respectively[7].

Bacillus thuringiensis serovar israelensis (Bti) a highly toxic bio-pesticide to dipteran larvae, opened up the probability of the use of these bio-larvicides in mosquito eradication programmes[9]. The major advantage of Bti over other mosquitocidal bacteria is that the Bti produce multiple intracellular crystal (134, 125, 67, and 27 kilo Daltons) inclusions in sporulation[10]. The various waste materials (industrial waste and agricultural derivatives) have used effectively as a substitute to commercial culture media for producing mosquitocidal bacteria (Bs and Bti) to utilize vector control practice. The present research in our laboratory is effectively used chicken feather waste from poultry forms to produce bacterial (B. thuringiensis subsp israelensis) culture for bio-pesticide[11]. The purification and characterization of the enzyme, produced by Bti, responsible for the biodegradation of feather waste is reported[12].

For the first time, the enzyme was purified and characterized by examined exploitation of Keratinase industrially in hydrolysis, the keratin substrate by using the Bti to produce the mosquitocidal toxins. Thus, the earlier report showing some Bacillus strains produced keratinolytic enzyme[8]. However, there is no report existing as on date on keratinolytic action of Bti to degrade keratin from feathers as functional unit. Most microbial keratinases are inducible enzymes[13]. Various keratinous materials such as chicken feather, feather, wool, meal and bovine hair have been employed as inducers of keratinases[14]. In the present study, we have purified the keratinase and it was similar to purification made from Bacillus sp[15]. The current investigation was successfully explored purification of Keratinase enzyme by the presence of distinct band on the SDS-PAGE which showed approximately 40 kD and results contemporaneous similar with previous reports were displayed by Keratinase from B. licheniformis FK14 (35 kDa), Streptomyces Pactum DSM 40530 and Doratomyces microsporus (30 – 33 kDa)[16]. However, keratinase with wide molecular mass range (18, 40 and 130 kDa were reported from Streptomyces albidoflavus, Streptomyces thermoviolaceus and Fervidobacterium pennavorans respectively[17] and Chrysosporium keratinophilum (69 kDa).

The examination of sequence for characterization of Keratinase in present study has showed that it is a surface layer protein, having advanced binding affinity towards keratin. Because, keratin proteins have preserved molecular structure (α-helical) having the property of multiple adherence activities with surface protein. Similar studies on the association between surface layer protein and keratin were reported previously from Staphylococcus aureus and Streptococcus agalactiae[18]. Hence, our results are concurrence with previous reports.

The appropriate pH of Bti Keratinase was found at neutral pH which was similar to earlier report by[19] for Bacillus sp. This is in difference from other alkaline keratinases. The enzyme was stable at the range of 6 - 8[8,13] Bacillus sp., FK 46 at 37°C[20], B. licheniformis PWD-1 at 50°C[21]. But in contrast to this alkaline keratinases with optimal pH 11.0 were also observed from Bacillus halodurans[15]. They are effectively active approximately pH10 with a molecular range between 10 and 30 kDa and isoelectric point around pH 9.0. This type of protease is produced by the variety of Bacillus species like B. halodurans, B. subtilis and B. licheniformis[22].

The concentration PMSF and EDTA can inhibit purified Keratinase activity even at 1mM, which reveals the serine type protease inhibitor. Similar examination was accounted for proteases exhibiting keratinolytic activity from Streptomyces and Bacillus species[22]. The strong inhibitory effect by EDTA indicated the importance of metal ions for activity/stability[23]. Present results indicated the magnitude of MgCl2 in feather degradation which was acknowledged by the results demonstrated that Amazonian bacterium (Bacillus sp. P45) enhanced the feather degradation by the presence of MgCl2 in feather media[23]. Similarly, protease production by a haloalkaliphilic bacterium was shown to be slightly stimulated by MgCl2, but inhibited MgCl2 [24]. The majority of Keratinase enzymes produced from bacteria are discharged in extracellular. Enzymatic degradation of chicken feather waste required the combined effect of reducing agents, because of single agent alone cannot be feasible to improve the enzymatic activity. The admiring feather concentration for the Keratinase was decided to be 4 mg/ml. Earlier report showed that the high concentration of feather waste was the reason for substrate inhibition or suppression of fabrication[20], on the other hand, high substrate concentration might enhance the medium viscosity, which possibly results in oxygen limitation for bacterial growth[25].

The new Keratinase enzyme was isolated, purified and characterized from B. thuringiesis serovar israelensis to degrade the keratin containing waste. The outcome recommended the prospective utilization of Keratinase in industrial to hydrolyze keratin for the fabrication of bacterial toxin (134, 125, 67 and 27 kDa). This bacterium can make hydrolytic enzyme and the most favorable conditions required by the enzyme for its proteolytic action was characterized and recommended that the mosquitocidal toxin production by using poultry processing waste in throughout the world, under the favorable condition for appropriate degradation of feather wastes. Hence, this finding is a great deal with production of bio-pesticide from mosquitocidal bacteria and other hands switch off the environmental waste.

Figure 1:

References

- 1. Onifade, A.A., Babatunde, G.M. Comparison of the utilization of palm kernel meal, brewers’ dried grains and maize offal by broiler chicks. (1998) Br Poult Sci 39(2): 245-250

- 2. Yamamura, S., Morita, Y., Hasan, Q., et al. Characterization of a new keratin-degrading bacterium isolated from deer fur. (2002) J Biosci Bioeng 93(6): 595-600.

- 3. El-Refai, H.A., Abdel Naby, M.A., Gaballa, A., et al. Improvement of the newly isolated Bacillus pumilus FH9 keratinolytic activity. (2005) Process Biochemistry 40(7): 2325-2332.

- 4. Bernal, C., Diaz, I., Coello, N. Response surface methodology for the optimization of Keratinase production in culture medium containing feathers produced by Kocuria rosea. (2006) Can J Microbiol 52(5): 445 - 450.

- 5. Tatineni, R., Doddapaneni, K.K., Potumarthi, R.C., et al. Purification and characterization of an alkaline Keratinase from Streptomyces sp. (2008) Bioresour Technol 99(6): 1596-1602.

- 6. Wang, H.Y., Liu, D.M., Liu, Y., et al. Screening and mutagenesis of a novel Bacillus pumilus strain producing alkaline protease for dehairing. (2007) Lett Appl Microbiol 44(1): 1- 6.

- 7. Riessen, S., Antranikian, G. Isolation of Thermoanaerobacter keratinophilus, a novel thermophilic, anaerobic bacterium with keratinolytic activity. (2001) Extremophiles 5(6): 399–408.

- 8. Lee, Y.J., Kim, J.H., Kim, H.K., et al. Production and characterization of Keratinase from Paracoccuc sp. WJ.98. (2004) Biotech and Biop Eng 9: 17-22.

- 9. Goldberg, L.H., Margalit, J. A bacterial spore demonstrating rapid larvicidal activity against Anopheles sergentii, Uranotaenia unguiculata, Culex univitatus, Aedes aegypti and Culex pipiens. (1977) Mosq News 37(3): 355-358.

- 10. Wirth, M.C., Delecluse, A., Federici, B.A. et al. Variable cross-resistance to Cry-IIB from Bacillus thuringiensis subsp. jegathesan in Culex quinquefasciatus (Diptera: Culicidae) resistant to single or multiple toxins of Bacillus thuringiensis subsp. israelensis. (1998) Appl Environ Microbiol 64(11): 4174-4179.

- 11. Poopathi, S., Abidha, S. Biodegradation of poultry waste for the production of mosquitocidal toxins. (2008) Int Biodeterioration and Biodegradation 62(4): 479 – 482.

- 12. Poopathi, S., Mani, C., Rajeswari, G. Potential of Sugarcane Bagasse (agro-industrial waste) for the production of Bacillus thuringiensis israelensis. (2013) Trop Biomed 30(3): 504-515.

- 13. Cheng, S.W., Hu, H.M., Shen, S.W., et al. Production and characterization of Keratinase of a feather degrading Bacillus licheniformis PWD–1. (1995) Bios Biotec and Biochem 59(12): 2239–2243.

- 14. Kumar, A.G., Swarnalatha, S., Gayathri, S., et al. Characterization of an alkaline active-thiol forming extracellular serine Keratinase by the newly isolated Bacillus pumilus. (2008) J App Microbiol 104(2): 411–419.

- 15. Shrinivas, D., Naik, G.R. Characterization of alkaline thermostable keratinolytic protease from thermo alkalophilic Bacillus halodurans JB 99 exhibiting dehairing activity. (2011) Int Biodeterioration and Biodegradation 65(1): 29-35.

- 16. Gradisar, H., Kern, S., Friedrich. J. Keratinase of Doratomyces microsporus. (2000) App Microbiol and Biotech 53(2): 196–200

- 17. Friedrich, A.B., Antranikian, G. Keratin degradation by Fervidobacterium pennavorans, a novel thermophilic anaerobic species of the order Thermotogales. (1996) Appl Environ Microbiol 62(8): 2875–2882.

- 18. Samen, U., Eikmanns, B.J., Reinscheid, et al. The surface protein Srr-1 of Streptococcus agalactiae binds human keratin 4 and promotes adherence to epithelial HEp-2 cells. (2007) Infect Immun 75(11): 5405-5414.

- 19. Vigneshwaran, C., Shanmugam, S., Sathish Kumar, T. Screening and characterization of Keratinase from Bacillus licheniformis isolated from Namakkal Poultry farm. (2010) Researcher 2(4): 89-96.

- 20. Suntornsuk, W., Suntornsuk, L. Feather degradation by Bacillus sp. FK 46 in submerged cultivation. (2003) Bioresource Technol 86: 239-243.

- 21. Williams, C.M., Richter, C.S., Mackenzie, J.M., et al. Isolation, identification, and characterization of a feather-degrading bacterium. (1990) Appl Environ Microbiol 56(6): 1509-1515.

- 22. Gupta, R., Ramnani, P. Microbial keratinases and their prospective applications: an overview. (2006) Appl Environ Microbiol 70(1): 21-33.

- 23. Daroit, D.J., Correa, A.P.F., Brandelli, A. Production of keratinolytic proteases through bioconversion of feather meal by the Amazonian bacterium Bacillus sp. P45. (2011) Int J Biodeterioration and Biodegradation 65(1): 45-51.

- 24. Joshi, R.H., Dodia, M.S., Singh, S.P. Production and optimization of a commercially viable alkaline protease from a haloalkaliphilic bacterium. (2008) Biotech and Biop Eng 13(5): 552-559.

- 25. Park, G.T., Son, H.J. Keratinolytic activity of Bacillus megaterium F7-1, a feather-degrading mesophilic bacterium. (2009) Microbiol Res 164(4): 478-485.